Nano-Engineering

Nanofiber Based Membrane

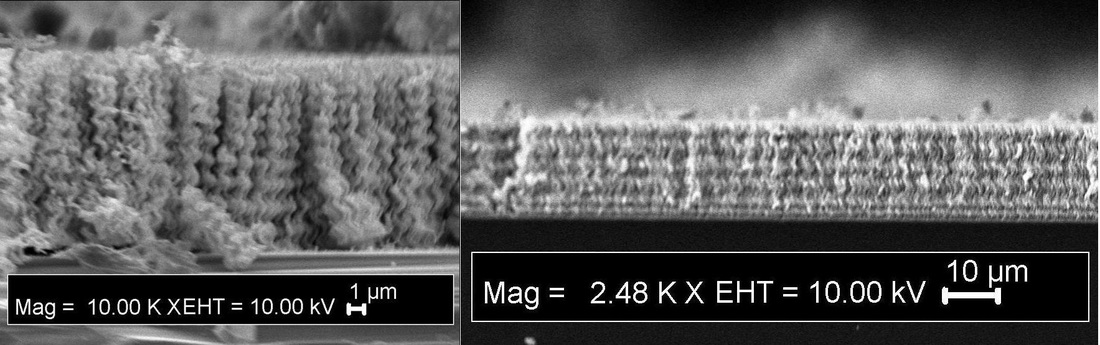

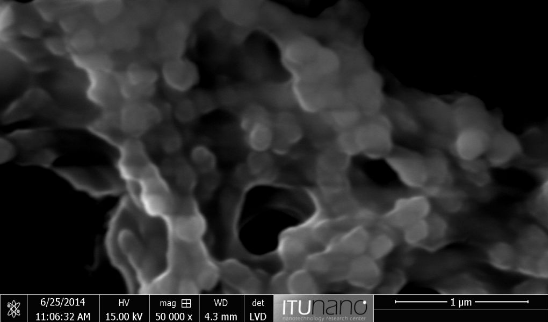

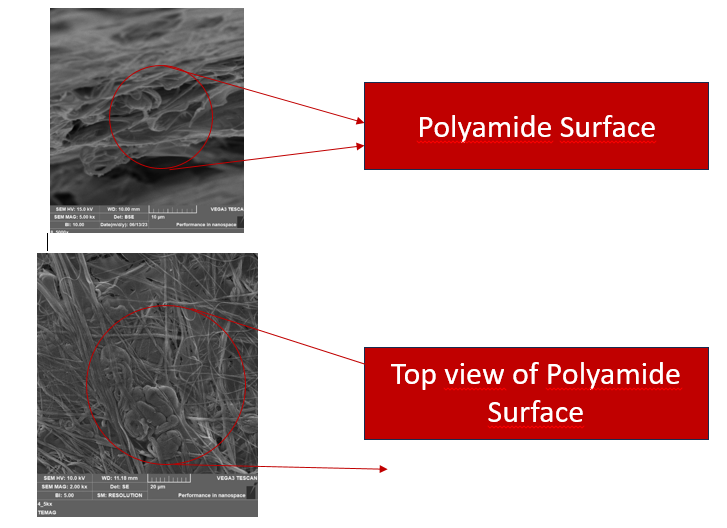

In this study, a polyamide thin film was synthesized on an optimized nanofiber substrate surface by using the interfacial polymerization method. The synthesized polyamide thin film purifies salt water by preventing the passage of salt ions in seawater. The material produced is prepared for use in Reverse Osmosis systems.The substrate surface is made by polysulfone nanofiber production. Improvements in pore diameter, mechanical strength, and surface properties were hot-pressed. With the hot press treatment method, the substrate surface was pulled up to 90o with a contact angle of 130o. Thus, the superhydrophobic surface was improved. While the average pore diameter was one micrometer and above before hot-pressing, it decreased to 200 nm after hot-pressin. Polymerization is synthesized using a vacuum filtration device. With vacuum power, the absorption of aqueous monomer solution into the hydrophobic substrate pore structures is achieved.

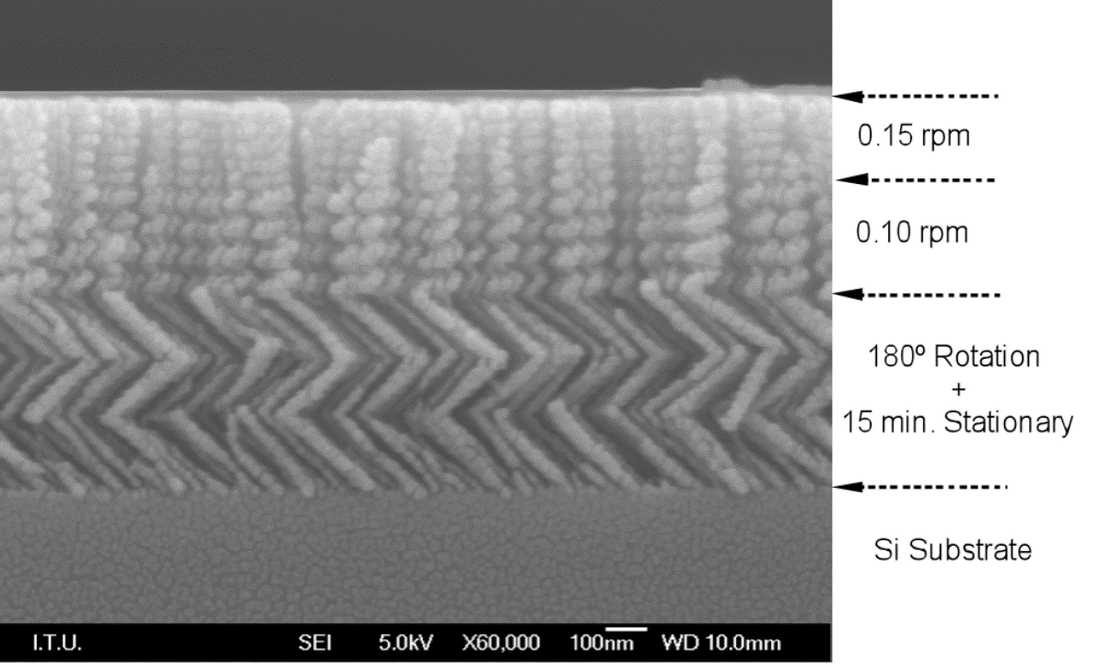

Sculptured Thin Films

We successfully deposit nano-columns with a thickness of 40 nm in 2300 microns. The nano-films are deposited by e-beam evaporation in a PVD System. The main aim is to integrate such films with MEMS technology. We are able to design nano-structures in 2-D (square-, triangular - and oval-crosssections) as well as 3-D (spirals, zig-zags). It is also possible to integrate different geometries in one column.

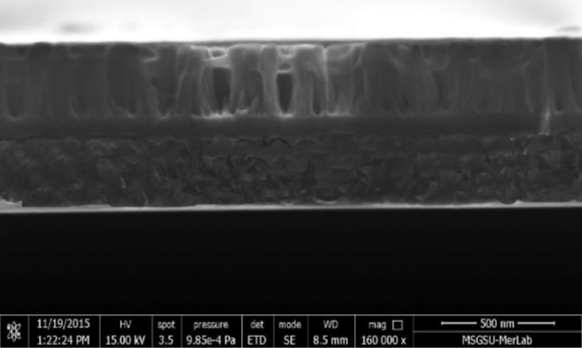

Fig. 1: The deposition of Si nano-columns in hybrid geometry.

Fig. 2: The top and cross-sectional views of Si-nano columns in columnar form with 2 (A), 3 (B) and 4 (C) degree of freedom grown with 85 incoming atomic flux angle to the substrate with 0.3 nm/sec growth rate and 0.35 rpm and 4 rpm for low and high turning speed, respectively, for 50 min. duration of deposition.

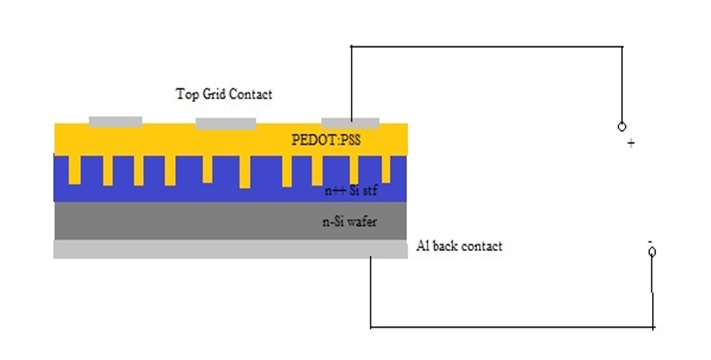

Solar Cells

In this study, highly doped (1018 atoms/cm3) amorphous silicon structured thin films and flat films are deposited by e-beam evaporation technique using Kurt J. Lesker equipment. Structured thin films were deposited at 80o to form slanted structures with no rotation and at 80o with 25 rpm to form vertical columnar structures. Then highly conductive and transperant PEDOT:PSS (Heraeus-Clevios) was coated onto silicon structured thin films and flat surface to create p-n junction.

Columnar structures possess lower reflectance value in UV-VIS spectroscopy which means they have higher absorbance so we can use these structures both for solar cell application and other opto-electronic devices as anti-reflection coating to increase efficiency and other PV parameters such as fill factor, open circut voltage and short circut density. Also columnar strucutres have hydrophilic surface due to the high porosity that characteristic eases the distribution of PEDOT:PSS hole conductor polymer on surface and provide better distribution and larger p-n junction interface area. Flat silicon has 98o while columnar structures possess 71o and 61o contact angle.

Cell Differentiation

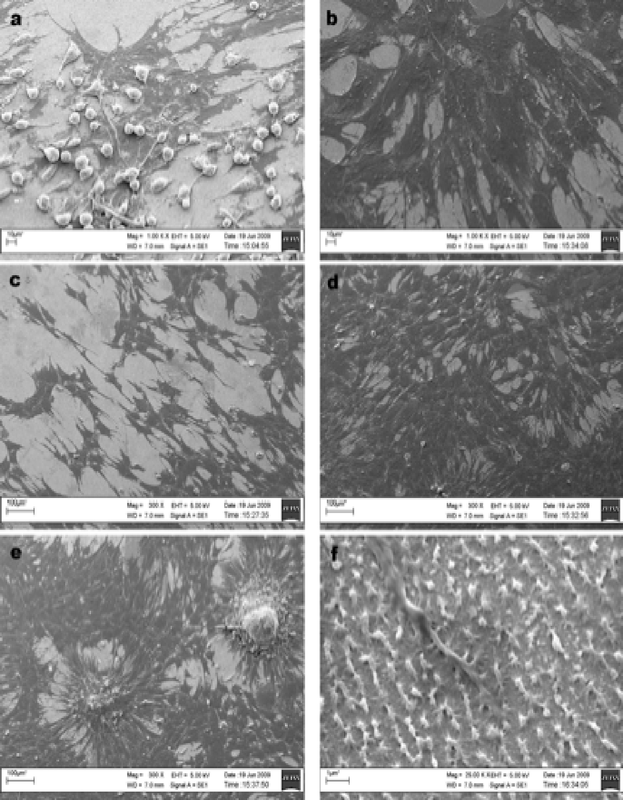

The adult stem cells are unspecialized cells found in many different tissues in the body, that appear to be able to yield all the specialized types of cells of that tissue. Examples are skin stem cells, which renew and repair our skin, and bone marrow stem cells give rise to bone cells, cartilage cells, fat cells, and other types of connective tissue cells such as those in tendons. While most of the studies for cell differentiation found in literature are based on the chemical signals, such as growth factors and protein interactions, some recent studies are also found on the physical affects that play a role on the cell behavior, such as mechanical stress, surface topography, and extracellular matrix (ECM). We have engineered nano-columns by thickness, cross-sectional profile and geometry in z-direction to study the cell behavior on a defined surface. Thus, the nano-columns will be grown periodically on the micro-scale predefined surface dots to have “nano-on micron” structures so as to mimic the natural biological environment that the stem cells experience in the tissue, and their behavior will be monitored precisely.

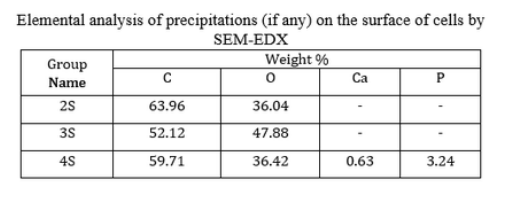

Fig. 2: Elemental analysis of precipitations (if any) on the surface of cells by SEM-EDX.

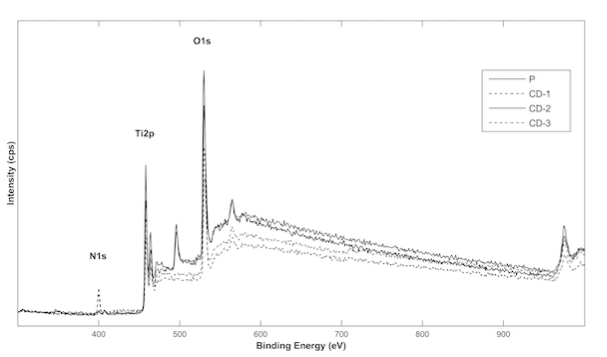

Photocatalytic Thin Films

Titanium dioxide has a great interest in metal oxide semiconductors due to its wide bandgap. Sol-gel process is a wet chemical route to synthesis of metal oxides such as TiO2 through hydrolysis and condensation mechanism. Numerous dopants have been reported for the enhancement of the photo catalytic activity of TiO2 such as nitrogen and iron. Our purpose is preparation and characterization of several TiO2 based films to alter optical properties and increase photocatalytic activity.

Polymer Nano-Composites

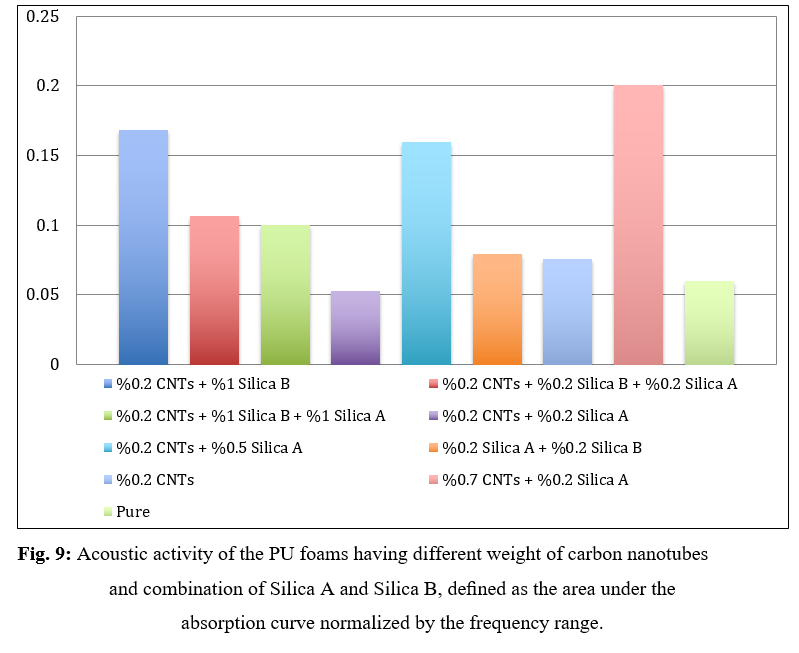

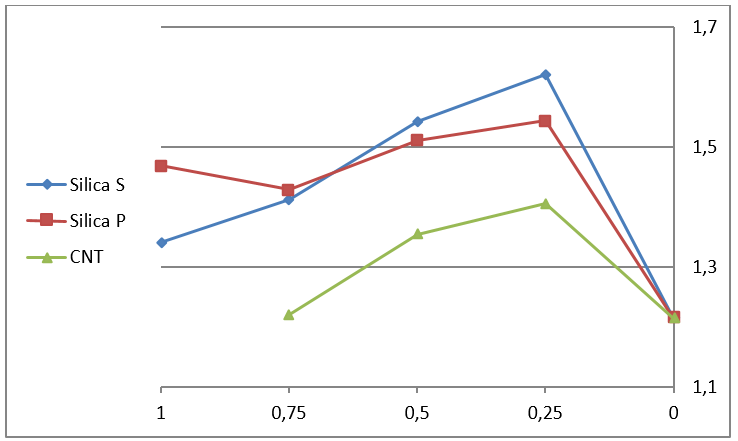

In order to enhance acoustic and mechanical properties of polyurethane foam, carbon nanotubes and/or silica nanoparticles up to 1 wt% were added to polyol & isocyanate composition. Acoustic properties, especially absorption coefficient of polyurethane reinforced with CNTs and silica nanoparticles (spherical and/or amorphous types) were determined in the frequency range up to 6400 Hz that can be applied for sound absorption application at the desired frequency range. We concluded that it is possible to obtain polyurethane nanocomposite with a higher amount of CNT at the same time enhancing sound absorption properties and there is a synergic effect between CNTs and silica nanoparticles when mixed and added into polyurethane matrix at predetermined levels, especially for determining the acoustic properties.

For investigating mechanical properties of produced nanocomposites, tensile tests and charpy impact tests were carried out. According to obtained results, adding small amount of CNTs and silica nanoparticles improve tensile and impact strength of the nanocomposites and mentioned synergic effect can be seen in mechanical properties.

Fig. 1: Acoustic activity of the PU foams having different weight of carbon nanotubes and combination of Silica-A and Silica-B, defined as the area under the absorption curve normalized by the frequency range.

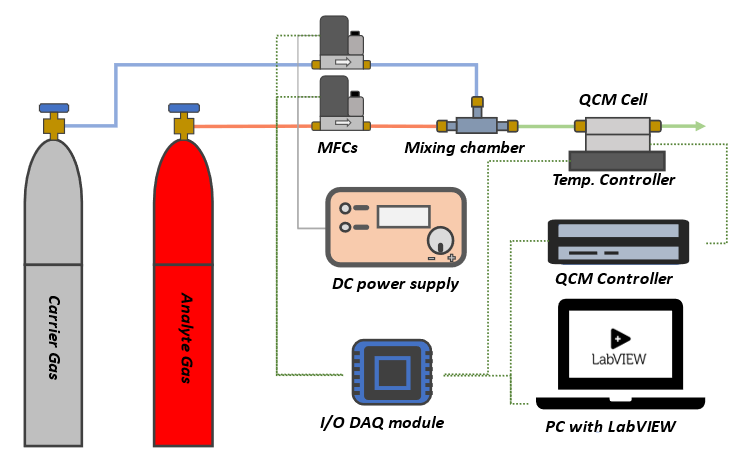

Gas Sensing and its Physics by QCM

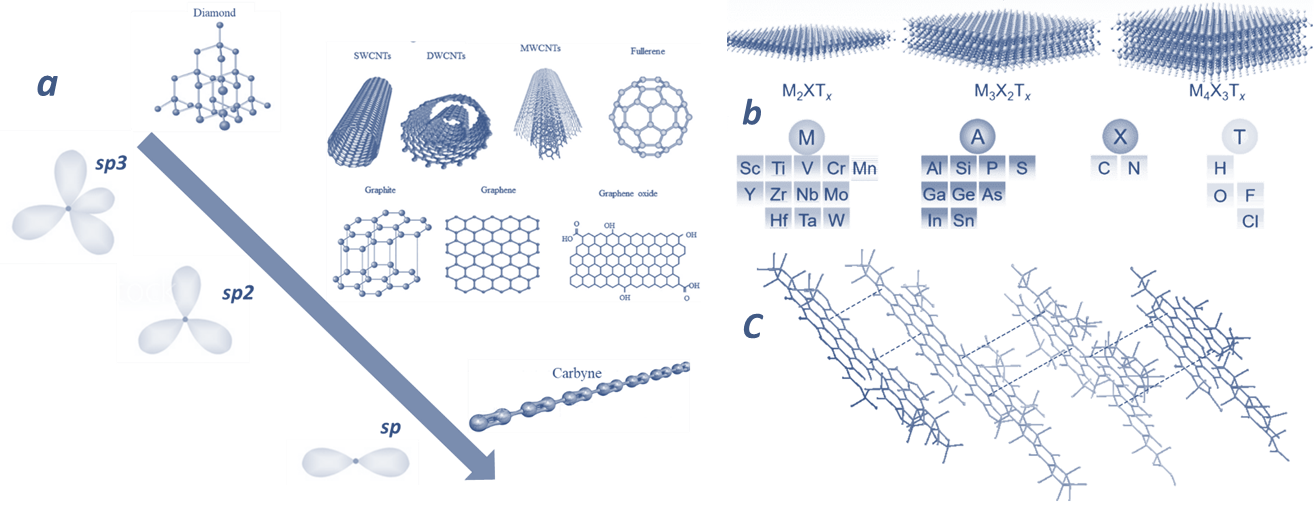

The target of this study is to fabricate novel carbon-based nanomaterial films with radical sensing properties, fully characterize their properties, and demonstrate their use as high-performance gas sensors. These films are going to be used as sensing material in acoustic quartz crystal microbalance (QCM) sensors to enhance the sensitivity and selectivity of these devices. In cooperation and coordination with several research institutes, the scope of this investigation will include different new materials such as the one-dimensional sp-hybridized carbon, called Carbyne, the two-dimensional MXenes, Nanoclays, and crosslinked Asphaltenes. Moreover, the integration of these materials with other already available carbon nanomaterials, such as 2D graphene and carbon nanotubes, is to be examined for exploring any possible synergistic effect and its influence on the sensing performance of their hybrid composites.

Figure 2. Schematic representation of involved materials: Carbyne (a), MXenes (b), and Asphaltenes (c).

Polymer-Nano-Composites to improve polyester for automotive applications

The research focused on fabricating polyester composites with incorporated MWCNTs and GNPs, assessing their impact on mechanical properties. Pure polyester samples served as the baseline for comparison. Gradual additions of GNPs at 0.2%, 0.4%, and 0.6% weight concentrations were individually studied, followed by a similar process with MWCNTs. This stepwise approach enabled the evaluation of the singular effects of each nano-additive. Subsequently, composite manufacturing involved combining MWCNTs and GNPs in ratios of 3:1, 1:3, and 1:1 within the polyester matrix. Tensile testing of these compositions provided comprehensive insights into their mechanical behaviors. This systematic exploration of various concentrations and combinations of MWCNTs and GNPs within polyester offers a nuanced understanding of their synergistic effects on composite tensile properties.

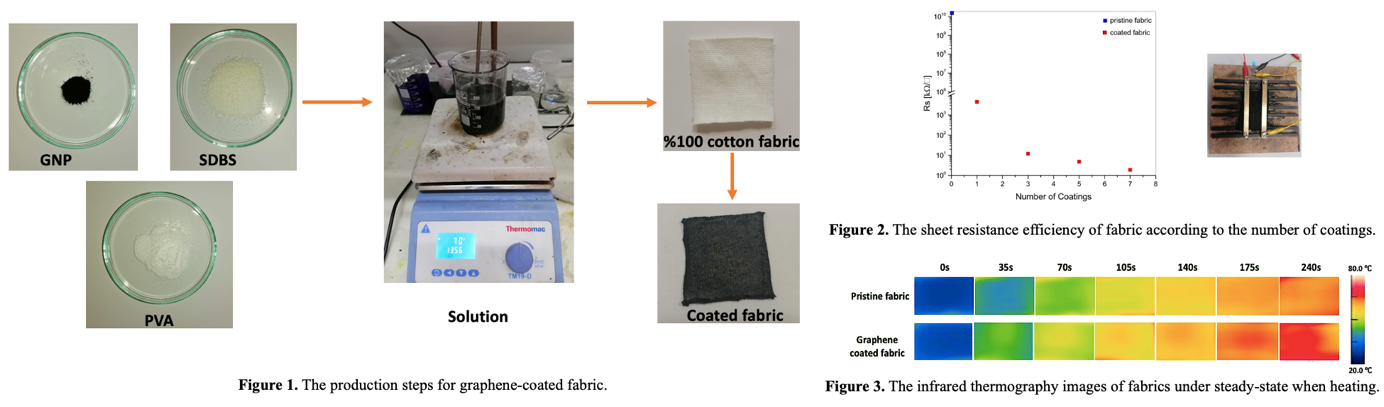

Designing and Development of Nano-Enhanced Thermal Conductive Textiles

The scope of this project encompasses the design and production of highly scalable functional e-textiles using a water-based graphene solution. The project involves the preparation of water-based graphene nanoplatelet (GNP) dispersions with sodium dodecyl benzene sulfonate (SDBS) as a surfactant and polyvinyl alcohol (PVA) as a binder. Dispersion application to cotton fabric involves a dip-pad-dry method. This process results in a strong interaction between fibers and the graphene dispersion. The outcome is a significant improvement (up to 60%) in the tensile strength, electrical conductivity, and thermal behavior of fabrics compared to pristine fabric. Also electro-mechanical tests showed resistance of functionalized fabrics has a great response to the strain.