Micro-Engineering (MEMS)

Design and Simulation

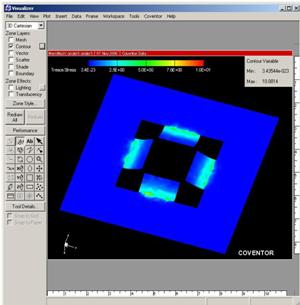

Design and simulation is the main part of the experimental work, thus it is performed prior to the experimental studies. We have utilized the following softwares: ANYSYS, CoventorWare and Comsol-MEMS modules.

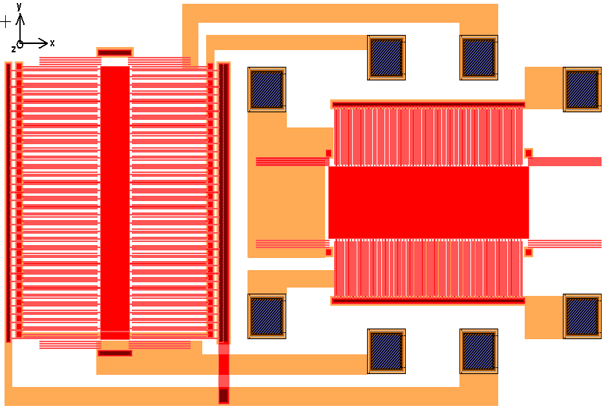

Fig. 2: Layout of designed accelerometers which are composed of gap changing and overlap area changing MEMS accelerometer.

Compliant-MEMS

Micro-compliant systems enable force and motion through elastic beams, and play an important role in MEMS due to their mechanical advantages. We are able to desgin and fabricate C-MEMS (Compliant-MEMS) to induce force magnification. We performed topografy optimization in order to improve response of the system for a given input.

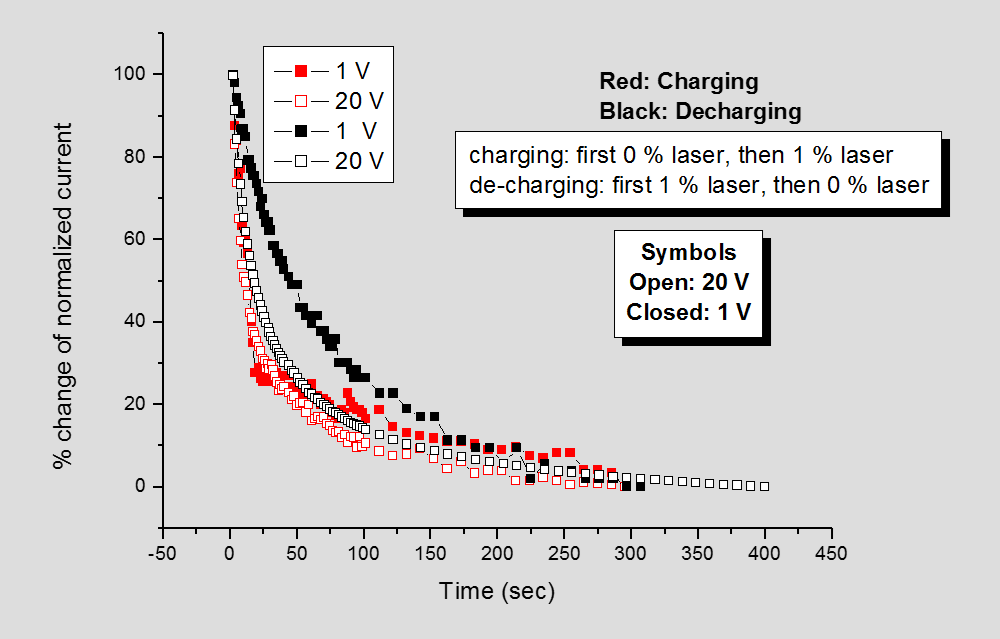

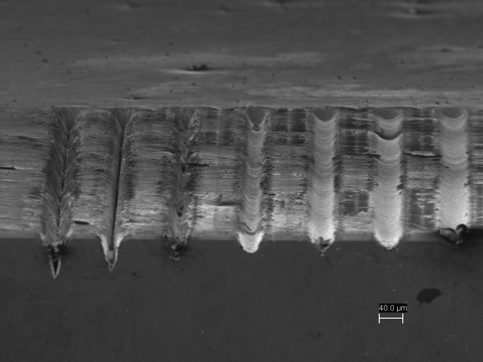

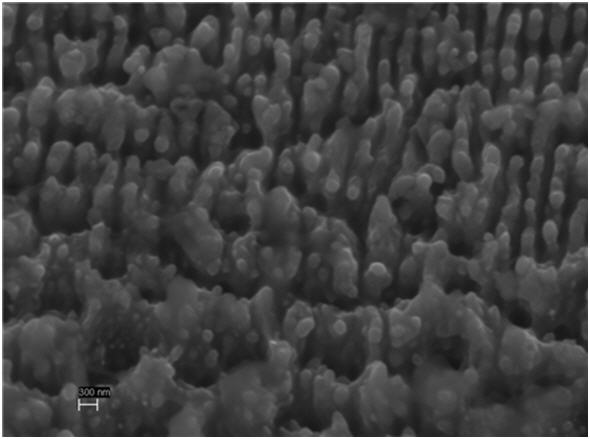

Microfabrication by Laser

Our purpose is to create periodic and controlled nano spike with femtosecond LASER on silicon surface without using any masks procedure which is used lithography and subsequent to etching dry or wet when, all of these levels are more expensive method in contrast with previous one.